Glass-Fused-to-Steel (GFS), also known as Glass-Lined-Steel (GLS), is the ultimate tank and silo solution utilizing a proven product with significant benefits to customers, consultants and contractors over other types of tank and silo construction.

Long-life and durability are reputations that can only be gained by dedication to the highest quality and commitment to ZERO DISCONTINUITY glass fusion (defect free at test voltage); this philosophy is enshrined in Permastore’s procedures.

WHAT IS GLASS-FUSED-TO-STEEL?

Glass-Fused-to-Steel (Glass-Lined-Steel) is a unique tank finish. Two materials are fused together to achieve the best properties of both – the strength and flexibility of steel combined with the corrosion resistance of glass. Applied to both interior and exterior surfaces, Glass-Fused-to-Steel is able to provide many years of trouble free service in harsh environments. This system has been proven over many decades on thousands of installations, and is supported by International Standards which cover the design and finish requirements:

International Quality Management Standard – ISO 9001:2008 accreditation of quality standards to guarantee Customer satisfaction.

International Standards – Permastore’s quality systems ensure that products meet or exceed the requirements of EN ISO 28765:2016*, AWWA D103-09, EEA 7.20, 7.24 and 7.25 amongst others. PERMASTORE® structures are engineered with a predicted minimum 30 year design life in accordance with the requirements of ISO 15686-1:2011, ISO 15686-2:2012 and ISO 15686-3:2002 which provide the framework for determining and planning a service life of 60 years and beyond.

International Bodies – Permastore Quality Standards and product testing are independently audited by MPA NRW. Certified to NSF/ANSI 61. Approved by the UK Secretary of State under Regulation 31 for drinking water and listed by DWI (Drinking Water Inspectorate) in its List of Approved Products. CE Marking Accreditation for steelwork ancillaries associated with Permastore designed storage tanks. Welding Management System complies with ISO 3834 Part 4 EWF/IIW requirements.

Environmental Management – Permastore holds ISO 14001:2004 Accreditation which provides reassurance to customers that we are focused on our social corporate responsibility and the environmental aspect of what we do.

The modular bolted tank construction principal allows the ‘factory quality’ finished panels to be economically shipped to site and erected within very tight timescales to meet customer requirements.

*Note EN ISO 28765:2016 Vitreous and porcelain enamels – Design of bolted steel tanks for the storage or treatment of water or municipal or industrial effluents and sludges, covers both the glass coating requirement and the tank structure design and as such is the first dedicated international standard specifically created for the Glass-Fused-to-Steel product applicable for water and wastewater applications.

International Standards

NST’s quality systems ensure that products meet or exceed the requirements of EN ISO 28765:2016*, AWWA D103-09, EEA 7.20, 7.24 and 7.25 amongst others. Our structures are engineered with a predicted minimum 30-year design life in accordance with the requirements of ISO 15686-1:2011, ISO 15686- 2:2012 and ISO 15686-3:2002 which provide the framework for determining and planning a tank lifecycle of up to 60 years and beyond.

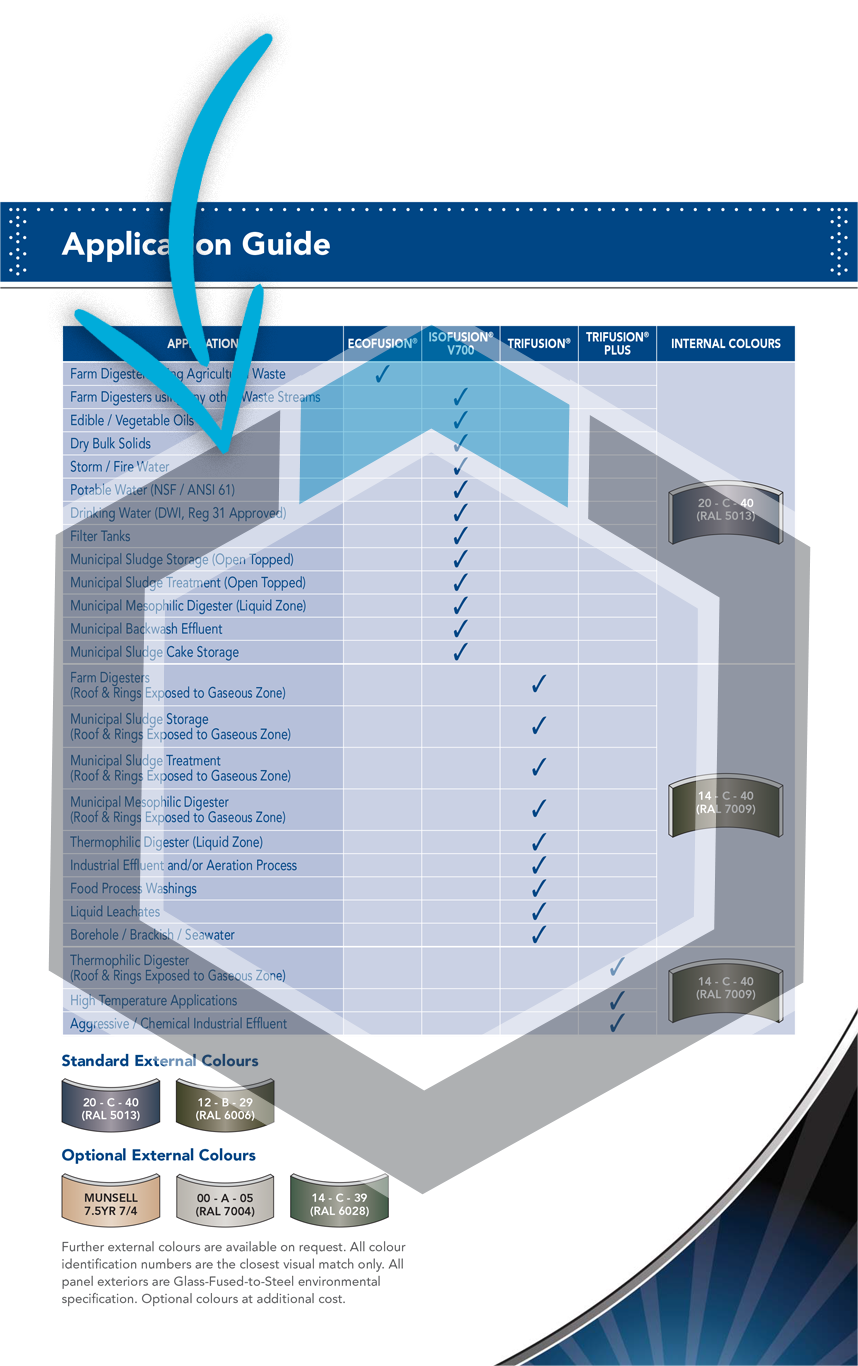

APPLICATION GUIDE

The application guide below indicates NST’s range of finishes for the majority of storage and process applications. CLICK HERE TO DOWNLOAD.