STORAGE TANK SERVICE & SUPPORT AT A MEASURABLE VALUE

Water storage tanks represent important capital assets and are critical to a community’s operating system. Catastrophic failures of water storage tanks are extremely rare but can occur if required inspections and recommended maintenance have not been performed throughout the tanks’ performance life. When owners select a glass-fused-to-steel bolted storage tank, they select a tank with one of the lowest maintenance requirements of any tank available today. As noted in Glass-Fused-to-Steel bolted storage tanks operations and maintenance manuals, tanks call for annual inspection and maintenance to maintain and achieve the tanks optimum design and service life. Regular inspections and maintenance should be carried out in accordance with the recommendations and instructions carried out by the manufacturer or the contractor who installed the tank.

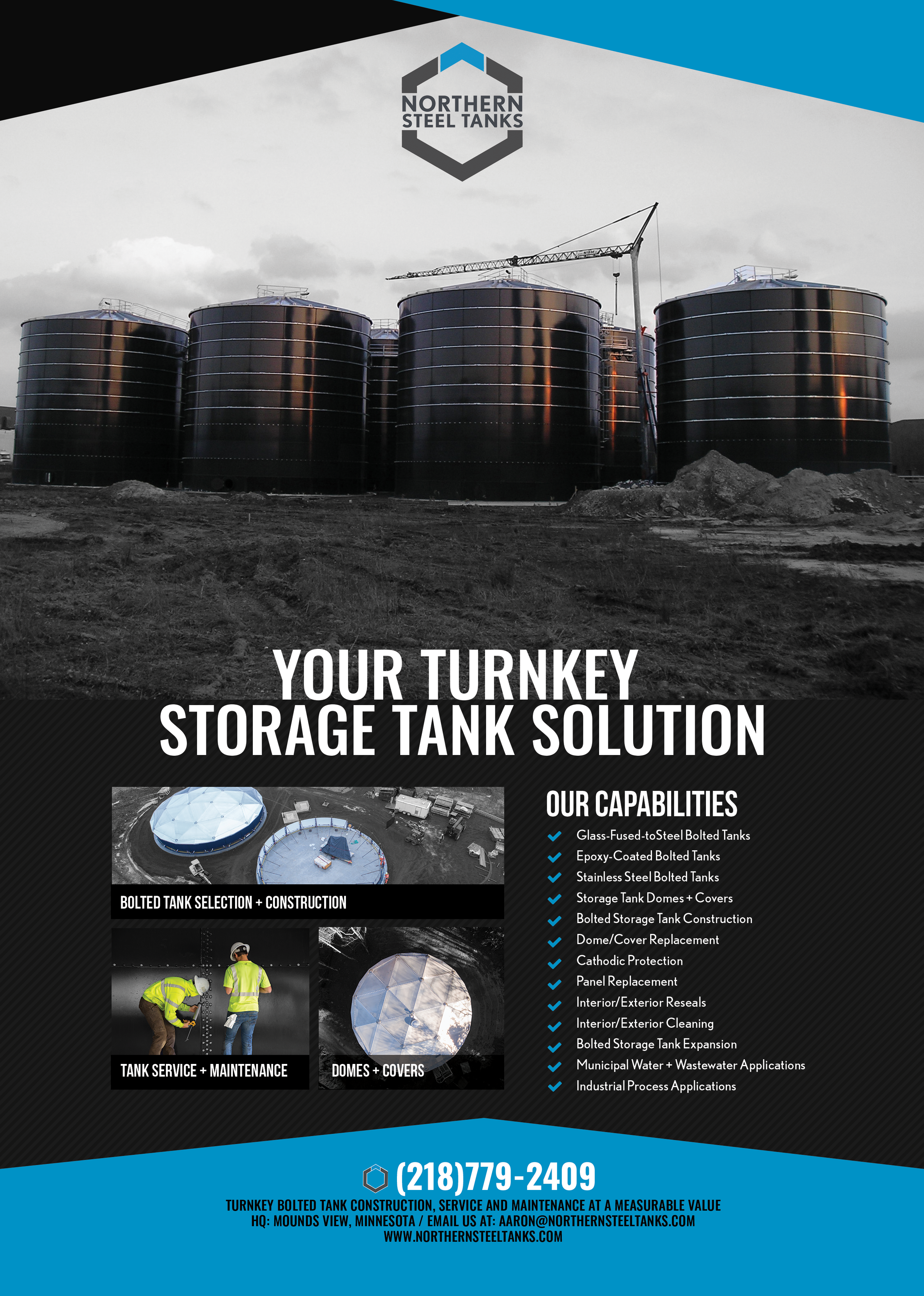

At a time when end-users are looking to expand the life of their aging water and wastewater infrastructure assets as long as possible, NST has had measurable success expanding the life of storage tanks with maintenance and services that include: tank expansion, interior & exterior reseal, panel replacement, surface cleaning, and inspections.

TANK CONSTRUCTION

NST’s team of project managers and construction personnel have built a solid reputation for integrity and commitment to our clients. We employ and train some of the top tank builders in the nation for the sole purpose of installing and maintaining bolted storage tanks. We will help you select the RIGHT PRODUCT for YOUR UNIQUE APPLICATION and DESIGN requirements.

INSPECTIONS (INTERIOR & EXTERIOR)

CATHODIC PROTECTION

Glass-Fused-to-Steel Tanks’ passive cathodic protection system consists of sacrificial anodes designed to protect the rebar, mitigate corrosion and provide protection to internal submerged metallic surfaces of the tank. The system is simple and reliable and requires only minimum maintenance.

PANEL REPLACEMENT

Severe storm damage or vandalism can leave your tank in need of repair. NST’s experienced, professional team replaces panels with precision to make your tank as good as new.

EXTERIOR SURFACE CLEANING

NST’s expert service team will give your tank a scheduled facelift. This is a smart way to maintain a beautiful tank. The team uses specialized cleaning equipment and techniques to remove stains, grime, mildew, and graffiti that inevitably build up over time, leaving a bright shiny, like-new tank in its place. The visual difference in the before and after is truly amazing and the value is clear.

SEALANT TOUCH-UPS

NST’s dedicated service team removes existing sealer and replaces it with new polyurethane sealer. They can also install optional HDPE plastic covers over exterior nuts and washers leaving a bright, clean, and refreshed tank. This process is a smart, cost-effective way to extend your tank’s service life.

INSULATION

NST offers tank insulation services to protect your tank and its contents from extreme temperatures. Not only is temperature control beneficial for the materials being stored, but by reducing the risk of damage and extreme heat, you’ll enjoy lower maintenance costs. Insulation comes in a variety of colors to fit your needs and can be installed with no interruption of service.

TANK EXPANSION

The bolted liquid storage tank has the ability to be expanded, which is an economical way to plan for future growth. Size your tank capacity for today’s requirements, but design your foundation for your future capacity. NST’s experienced crews will install our jacking system, unbolt the bottom connections and install the appropriate number of rings to raise the tank up to meet the designed maximum capacity. The only added cost at the initial purchase is the foundation which is designed for your maximum build-out. The additional cost of the heavier bottom rings comes at the time of expansion, providing an economical option for adding capacity to your system.

DOME AND COVER RETROFITS AND REPLACEMENTS

NST’s experienced field crews have had great success retrofitting our domes and covers on any existing tank including multi-terminal petrochemical sites.

WHY NST?

NST Tanks can be constructed in 1/3 of the time it takes to build concrete and welded tanks.

NST Tanks can be expanded to accommodate future capacity requirements.

NST’s unique tank construction utilizes the smallest construction footprint with little disturbance to the surrounding environment,

NST’s bolted tanks can be assembled in even the most remote sites, without large staging areas, during any season of the year.

NST’s bolted tanks are constructed at ground level using a jacking system that elevates the structure to install the panels without the need for expensive cranes, scaffolding, and equipment. Safety is job #1.

NST Tanks are designed to the highest quality global standards of any bolted tank in the global market.

NST Tanks are subjected to high-voltage integrity testing. Every single panel on the line is tested allowing us to maintain our zero-defect policy.

NST’s coatings are applied in the factory which means minimized construction delays due to weather compared to concrete and field-applied coatings.

NST Glass-Fused-to-Steel tanks never need painting and won't rust, corrode or chalk.